POLYGUARD Blue Barrier Liquid Flashing 20oz Sausage & Gap Filler

Polyguard

$264.79 - $341.79

RRP:

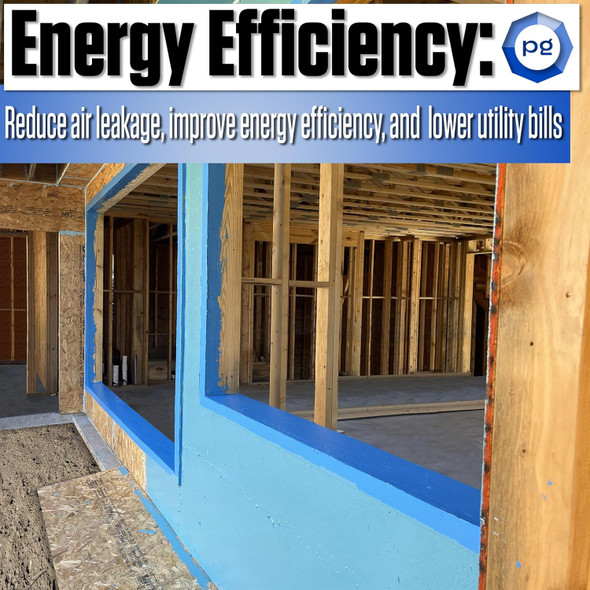

The Polyguard Blue Barrier™ Window & Door Flashing Kit is an all-in-one solution for professional-grade air and moisture sealing around window and door rough openings. This kit combines Blue...

Blue Barrier™ Liquid Wrap – Air & Moisture Barrier Membrane

Polyguard

$260.79 - $672.79

RRP:

BB LW is ideal for residential and light commercial projects requiring a durable, high-performance air and moisture barrier membrane. It is commonly used in conjunction with cladding or veneers and...

Polyguard UV2-40 | 40-Mil Rubberized Asphalt Air & Weather Barrier Membrane with Aluminum UV Protection – 36" x 33.3' Roll (Residential WRB/Flashing)

Polyguard

$136.79

RRP:

The Polyguard UV2-40 Membrane is a heavy-duty, 40-mil rubberized asphalt air and weather barrier designed for residential above-grade wall protection. Laminated to two layers of high-strength...

Polyguard® WindowSeal® Window Flashing Tape, 4-Pack

Polyguard

$139.79 - $391.49

RRP:

Polyguard WS20 WindowSeal 20 Mil Flashing Tape is a high-performance, self-adhering flashing solution for windows, doors, and construction seams. Designed to provide a waterproof, airtight seal, WS20...