Polyguard WM40 Waterproofing Membrane – 40 Mil Self-Adhering Sheet for ICF, CMU & Concrete Foundations (36" x 66.7' Roll, 200 sq. ft.)

Polyguard

$286.79

RRP:

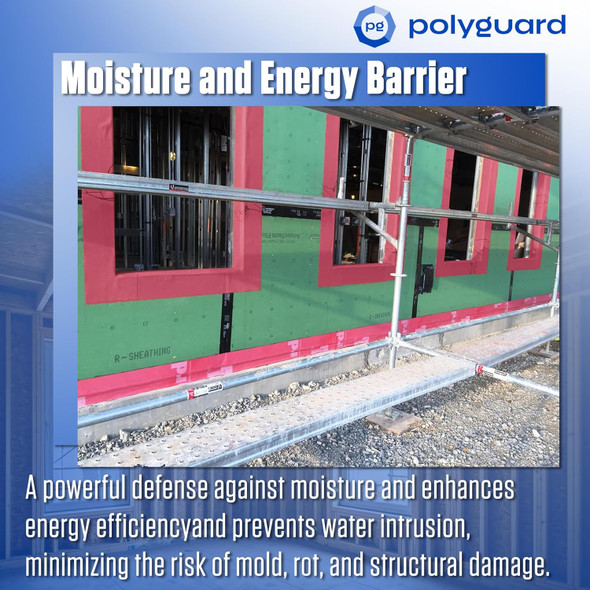

The Polyguard WM40 Waterproofing Membrane is a 40-mil thick, self-adhering sheet designed to protect below-grade foundation walls against water intrusion and hydrostatic pressure. Engineered with a...

TERM Flashing – 40 Mil Self-Adhered Termite & Waterproofing Barrier

Polyguard

$0.00 - $242.49

RRP:

TERM Flashing is a flexible, self-adhesive, non-structural membrane designed to act as a waterproofing, air, and pest exclusion barrier—specifically targeting the intersection between horizontal...

POLYGUARD Blue Barrier Liquid Flashing 20oz Sausage

Polyguard

$247.79 - $324.49

RRP:

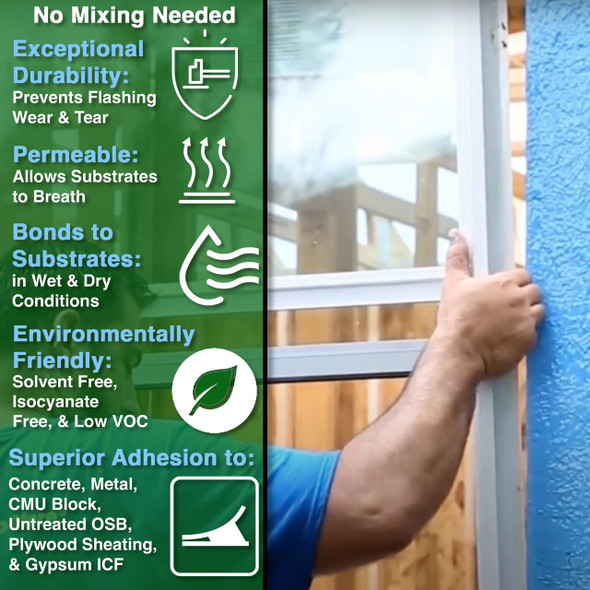

Polyguard Blue Barrier™ Liquid Flashing (BB LF) is a high-performance, fluid-applied flashing designed to provide a fully adhered, weather-resistant air barrier system for windows and door...

Polyguard® 650 TRM Termite & Waterproofing Membrane – Peel & Stick Barrier for Concrete Foundations & Walls (68 mil)

Polyguard

$315.79

RRP:

Polyguard® 650 TRM is a professional-grade, self-adhering waterproofing and termite barrier membrane designed to protect concrete foundations, vertical walls, ICF, plywood, and OSB structures. With a...

POLYGUARD Blue Barrier Liquid Flashing 20oz Sausage & Gap Filler

Polyguard

$264.79 - $341.79

RRP:

The Polyguard Blue Barrier™ Window & Door Flashing Kit is an all-in-one solution for professional-grade air and moisture sealing around window and door rough openings. This kit combines Blue...