AWF Pro® 2 ft. Professional Spray Foam Gun

AWF PRO

$55.79

RRP:

The AWF 1200 Professional 2' Foam Gun is a contractor-grade applicator engineered for precision, reach, and control. Its extra-long 2-foot nozzle allows professionals and serious DIYers to easily...

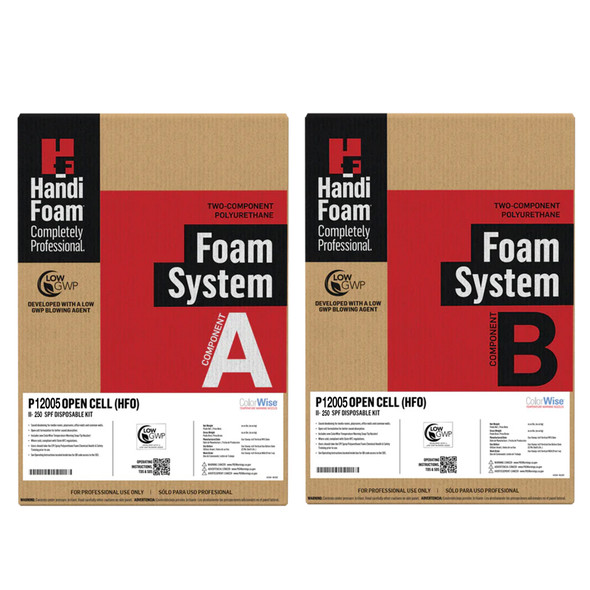

Handi-Foam Open Cell Spray Foam Insulation Kit – High Yield, Professional Grade, Easy Application

Handi Foam

$310.70 - $1,110.79

RRP:

Handi-Foam Open Cell Spray Foam Kits are professional-grade, low-density polyurethane foam systems designed to provide excellent thermal insulation and sound dampening. The open-cell structure...

AWF Pro® Heavy Duty Convertible Professional Spray Foam Gun

AWF PRO

$42.79

RRP:

$53.79

The AWF PRO 1500 Heavy Duty Foam Gun is a professional-grade applicator designed for high-performance use with both large one-component foam tanks and standard PRO foam cans. Engineered for...

AWF Pro® PTFE Non-Stick Coated Professional Spray Foam Gun

AWF PRO

$37.79

RRP:

$43.79

The AWF PRO 1400 Spray Foam Gun (100% Non-Stick Coated) is a professional-grade foam applicator engineered for superior performance, easy maintenance, and long-term durability. Fully coated with...

AWF Pro® PTFE Non-Stick Coated Professional Foam Gun, One Hand Adjustment

AWF PRO

$40.79

RRP:

The AWF 1800 Professional PTFE Non-Stick Coated Foam Gun is a durable, high-performance applicator specifically designed for use with professional-size foam sealant cans. Featuring a full PTFE...

AWF Pro® Professional Spray Foam Gun with PTFE Non-Stick Coated Adapter Basket

AWF PRO

$34.79

RRP:

The AWF PRO® 1000 Spray Foam Gun is a professional-grade applicator designed for use with Great Stuff™ PRO and other compatible polyurethane foam sealants. Built with precision in mind, this durable...