Vulkem® 116, Single-Component Polyurethane Sealant, Full Case (30, 10oz Cartridges), Select Your Color

Tremco

$173.79

RRP:

Vulkem® 116 is a single-component, textured, moisture-curing polyurethane sealant engineered for exterior use in dynamic construction joints. It is gun-grade, non-sag, and specifically designed to...

Vulkem® 45SSL Single-Component Polyurethane Joint Sealant – Pourable, UV Resistant, Traffic Grade, Full Case (12, 29oz Cartridges) and AWF PRO 18:1 Heavy-Duty 29oz Caulk Gun, Select Your Color

Tremco

$292.79

RRP:

This contractor-grade kit pairs 12 cartridges of Tremco Vulkem® 45SSL (29 oz) with the AWF PRO® 29 oz Caulking Gun, providing everything you need for high-performance horizontal joint sealing...

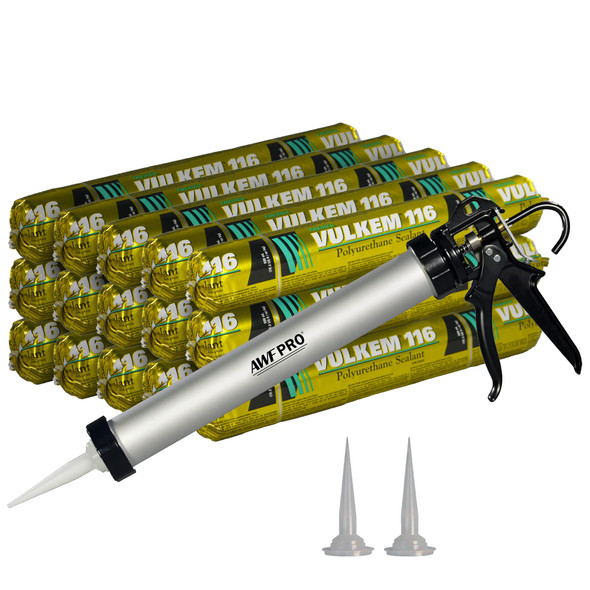

Vulkem® 116, Single-Component Polyurethane Sealant – Full Case (15, 20oz Sausage Packs) and AWF PRO 18:1 Sausage Gun, Select Your Color

Tremco

$202.79

RRP:

This heavy-duty sealant kit combines Tremco Vulkem® 116, a proven textured polyurethane sealant in a 20 oz sausage pack, with the high-performance AWF PRO 18:1 Sausage Caulk Gun—a dual-use applicator...

Vulkem® 116, Single-Component Polyurethane Sealant – Full Case (15, 20oz Sausage Packs), Select Your Color

Tremco

$172.79

RRP:

Vulkem® 116 is a single-component, textured, moisture-curing polyurethane sealant engineered for exterior use in dynamic construction joints. It is gun-grade, non-sag, and specifically designed to...

Sikaflex 15LM 10oz Low Modulus, Polyurethane Sealant with the AWF PRO 10oz Caulk Gun, 18:1 Thrust, Rotating Barrel, w/ pin on handle

Sika

$118.49 - $197.79

RRP:

This premium sealant kit brings together Sikaflex®-15 LM, a high-performance, low-modulus polyurethane sealant, with the AWF PRO 18:1 Caulk Gun, a contractor-grade applicator built for precision and...