Dymonic 100, 20 oz Sausage, Assorted Colors, Full Case

Tremco

$227.79

RRP:

This high-performance sealant kit pairs Tremco Dymonic® 100, a versatile, high-movement polyurethane sealant, with the durable and efficient AWF PRO 18:1 Sausage Caulk Gun. Built for pros who demand...

Dymonic FC, 20 oz Sausage, Assorted Colors, Full Case

Tremco

$175.79

RRP:

Dymonic® FC is a high-performance, fast-curing, single-component, low-modulus hybrid sealant designed with proprietary silane end-capped polymer technology. It provides a durable and flexible seal...

Dymonic FC, 20 oz Sausage, Assorted Colors, Full Case with Caulk Gun

Tremco

$205.79

RRP:

This high-performance sealant kit pairs Tremco Dymonic® FC, a fast-curing, low-modulus hybrid sealant, with the AWF PRO 18:1 Sausage Caulk Gun, a rugged, dual-use applicator engineered for precision...

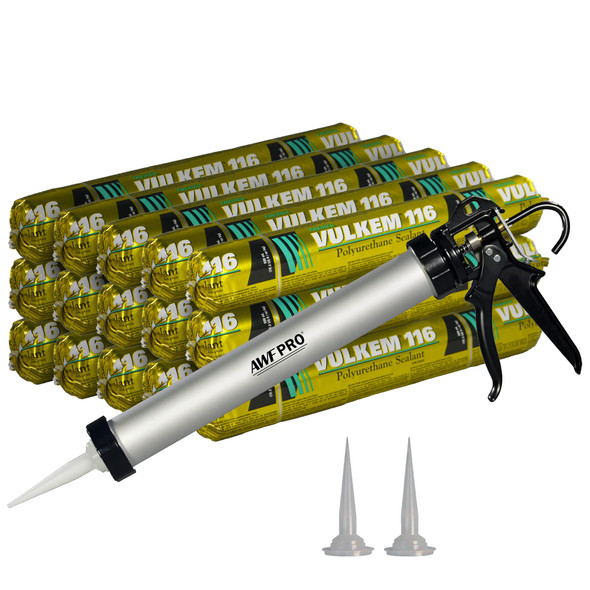

Vulkem 116, 20 oz Sausage, Assorted Colors, Full Case with Sausage Gun

Tremco

$199.79

RRP:

This heavy-duty sealant kit combines Tremco Vulkem® 116, a proven textured polyurethane sealant in a 20 oz sausage pack, with the high-performance AWF PRO 18:1 Sausage Caulk Gun—a dual-use applicator...

Vulkem 116, 20 oz Sausage, Assorted Colors, Full Case

Tremco

$169.79

RRP:

Vulkem® 116 is a single-component, textured, moisture-curing polyurethane sealant engineered for exterior use in dynamic construction joints. It is gun-grade, non-sag, and specifically designed to...